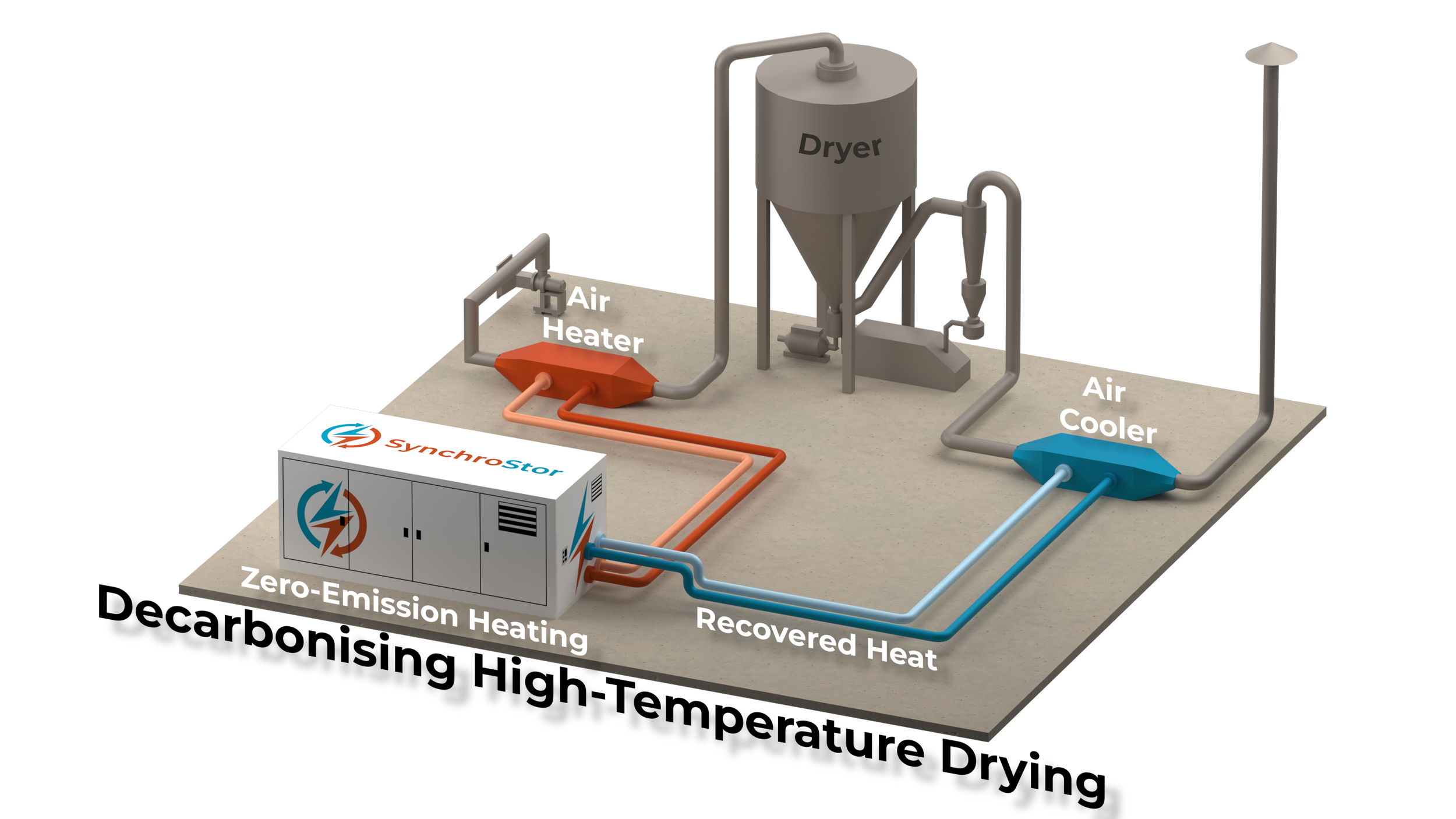

The Decarbonisation Solution for High Temperature Drying

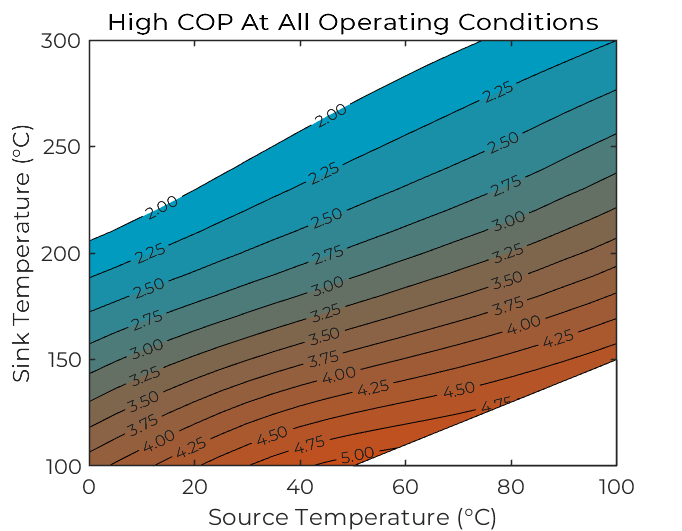

SynchroStor’s Heat Pump unlocks high temperatures at unparalleled efficiency for decarbonising the industrial high temperature drying sector.

⚡︎

Save Operating Costs

⚡︎

Easy Installation

⚡︎

Versatile

⚡︎ Save Operating Costs ⚡︎ Easy Installation ⚡︎ Versatile

Save Operating Costs

⚡︎ Unparalleled efficiency for short pay back

⚡︎ Eliminate emissions from fossil fuel heating

⚡︎ 75% lower electricity cost versus direct electric heating

Find Out More About Heat Pumps for High Temperature Drying in our Article

Easy Installation

⚡︎ Compact design for seamless integration

⚡︎ Compatible with any hot air-based drying system

Versatile

⚡︎ Fast start-up

⚡︎ Adapts to variable operating conditions

⚡︎ Instantaneous turndown for varying heat demand

Decarbonisation for High Temperature Drying

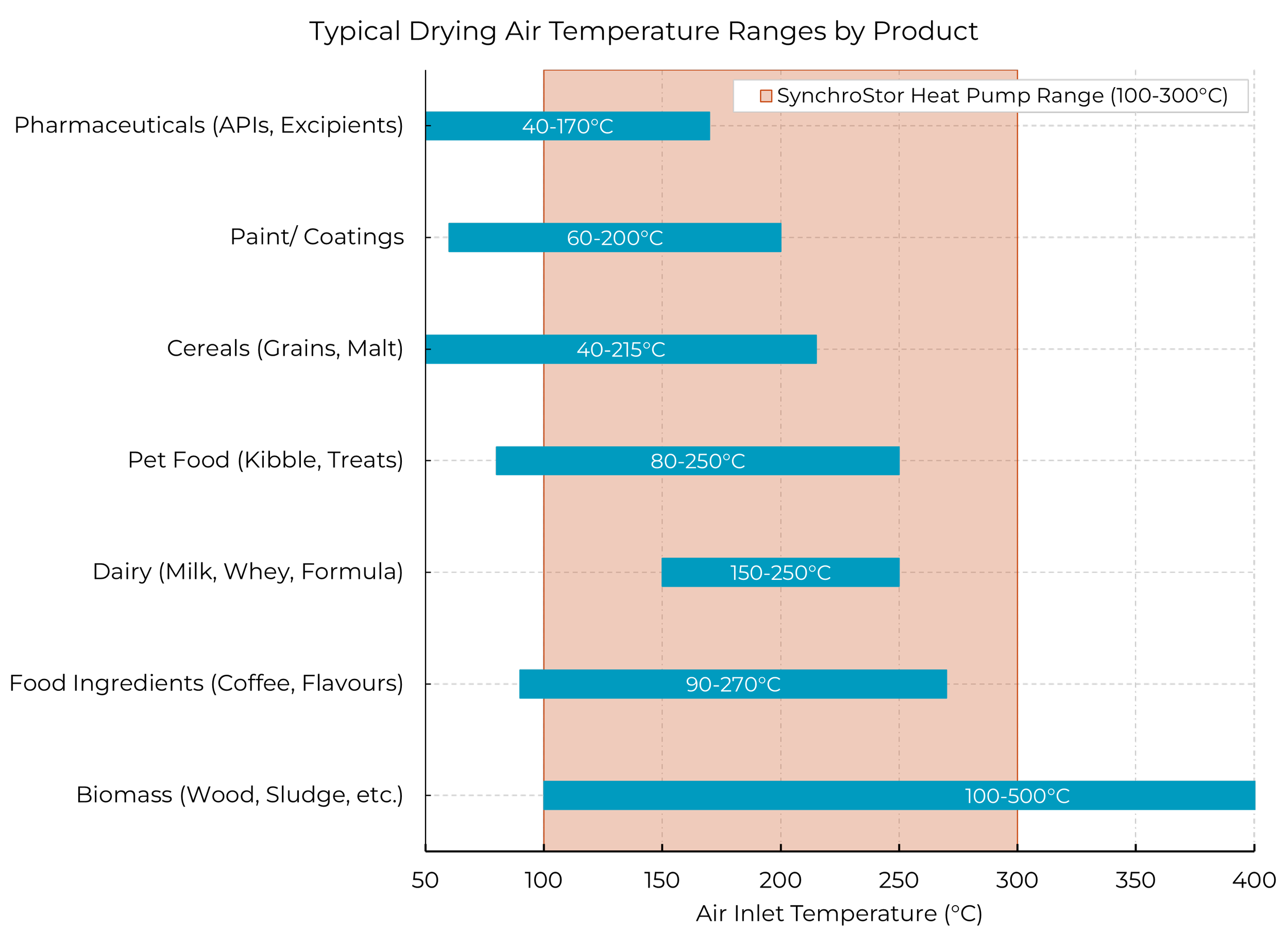

SynchroStor’s high-temperature heat pump technology delivers reliable hot air between 100°C and 300°C, covering the needs of a wide range of drying applications — from pharmaceuticals and coatings to food, dairy, and biomass.

By integrating SynchroStor’s heat pump, you can:

⚡︎ Decarbonise high-temperature drying across diverse industries

⚡︎ Achieve temperatures up to 300°C efficiently and sustainably

⚡︎ Maintain precise thermal control for sensitive drying applications

⚡︎ Unlock significant energy savings while reducing CO₂ emissions

Value Proposition

SynchroStor’s system enables complete electrification of drying operations previously dependent on fossil fuels, without compromising on process performance or temperature.

Reduce energy wastage by recovering waste heat from the dryer outlet and improve the efficiency of your operation.

Precise control reacts to process heat demand and external and internal temperature fluctuations. Saving you money and headaches during changing conditions.

Contact us now to see how SynchroStor can electrify your process

Heating ambient air from 15°C and utilising dryer outlet as heat source. Performance in different applications may vary.